Pneumatic Conveying System

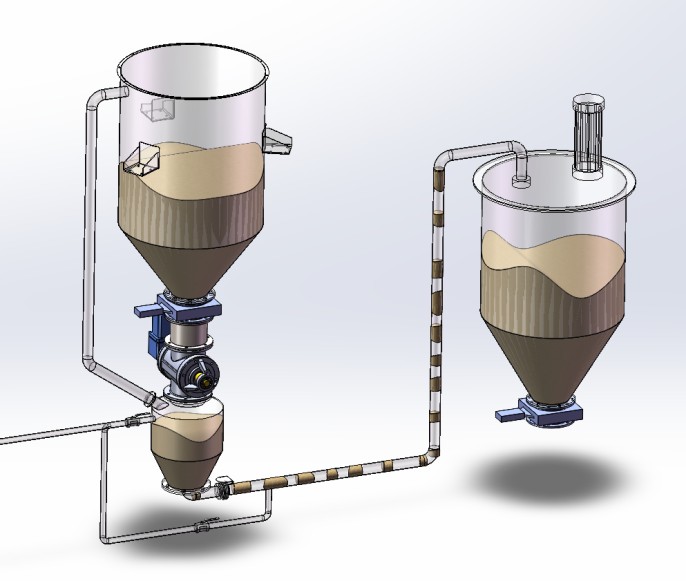

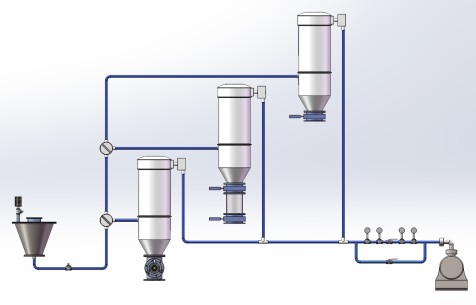

1.Dense Phase Conveying

Features and Benefits:

z Pressure range from 1 barg up to 6 barg, or more

z Conveying Rate up to 100m3/h

z High conveying efficiency and low air consumption

z High pressure and lower velocity to significantly reduce wear

z Suitable for fine fluidizable materials

z Larger vessel and smaller conveying pipes

z Suitable for conveying distances up to 6000 ft (1800 m)

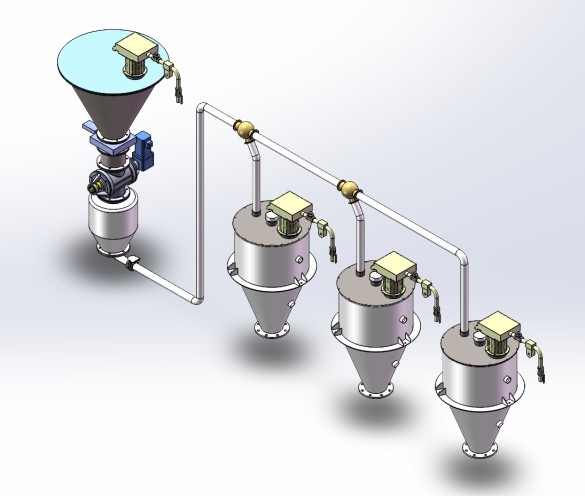

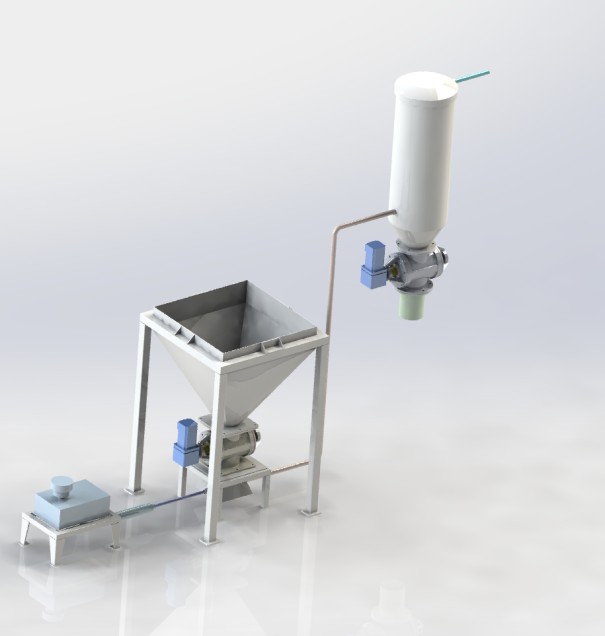

2.Dilute Phase Conveying

Features and Benefits:

z Pressure range from 0.4 barg up to 0. 6 barge

z Conveying Rate up to 60m3/h

z Low pressure and higher velocity

z Suitable for many non-sensitive and non-abrasive powders

z Little headroom necessary for installation

z Simple setup of the system

z Economical, reliable and budget friendly

z The throughput can be varied by controlling the rotational speed of the rotary valve

z Suitable for conveying distances up to 500 ft (150 m)

3.Vacuum Conveying

Features and Benefits:

z Fine and coarse powders, granules and bulky materials

z 50 to 2000kg/h, conveying distance varying from a short elevation up to 30m

z Weighed vacuum receiver for mixer filling

z Feeder refilling, both volumetric and gravimetric

z Automatic filter cleaning during the discharge cycle

z Batch or continuous transfer modes

z Dense phase systems can also be realized using high performance vacuum conveying systems

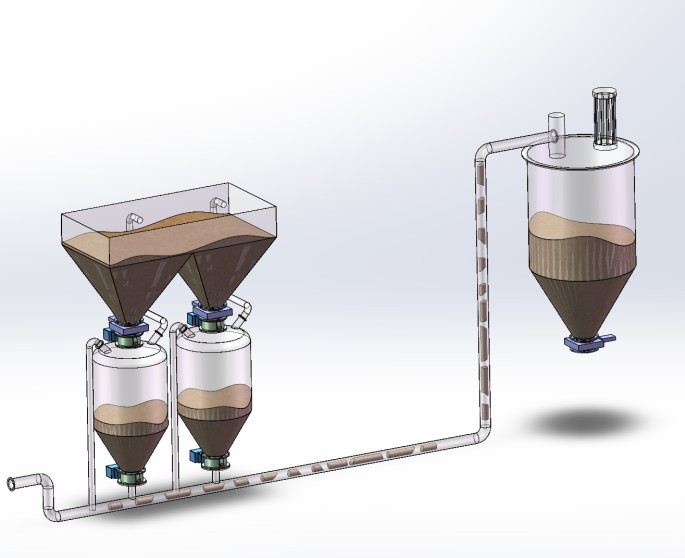

4 Soft Pneumatic Conveying

Features and Benefits:

z Pressure range from 1 barg up to 4 barg

z Conveying Rate up to 120m3/h

z High conveying efficiency and low air consumption

z The high loading and low velocity lead to gentle conveying and to low wear of both pipeline and receiver.

z Suitable for handling of fragile and lighter products

z Suitable for long conveying distances up to 3500 ft (1000 m)